<1250mm heightLincoln – Small Composite Driveway Gate

£2,310.00

Flat top, fully boarded, screwed composite gate

The ‘Lincoln’ composite gate is a twist on the traditional composite gate build. Each board is screwed top and bottom to the gate. With an additional screws in the middle of the gate spaced, 1 board screw – 2 boards no screws. Flat top, fully boarded, screwed composite gate.

This product is constructed from a premium-quality 50mm steel frame box section engineered for enhanced durability and structural integrity. The frame can undergo galvanisation and/or powder coating to provide superior protection against environmental factors. The gate features an infill composed of eco-friendly, recycled timber and plastic, positioning it as a leading solution in the category of maintenance-free composite driveway gates.

Please view our how to measure page to ensure you purchase the correct size gate.

Frame Specification

This product is constructed from a premium-quality 50mm steel frame box section engineered for enhanced durability and structural integrity. The frame can undergo galvanisation and/or powder coating to provide superior protection against environmental factors. The gate features an infill composed of eco-friendly, recycled timber and plastic, positioning it as a leading solution in the category of maintenance-free composite driveway gates.

Frame Specification

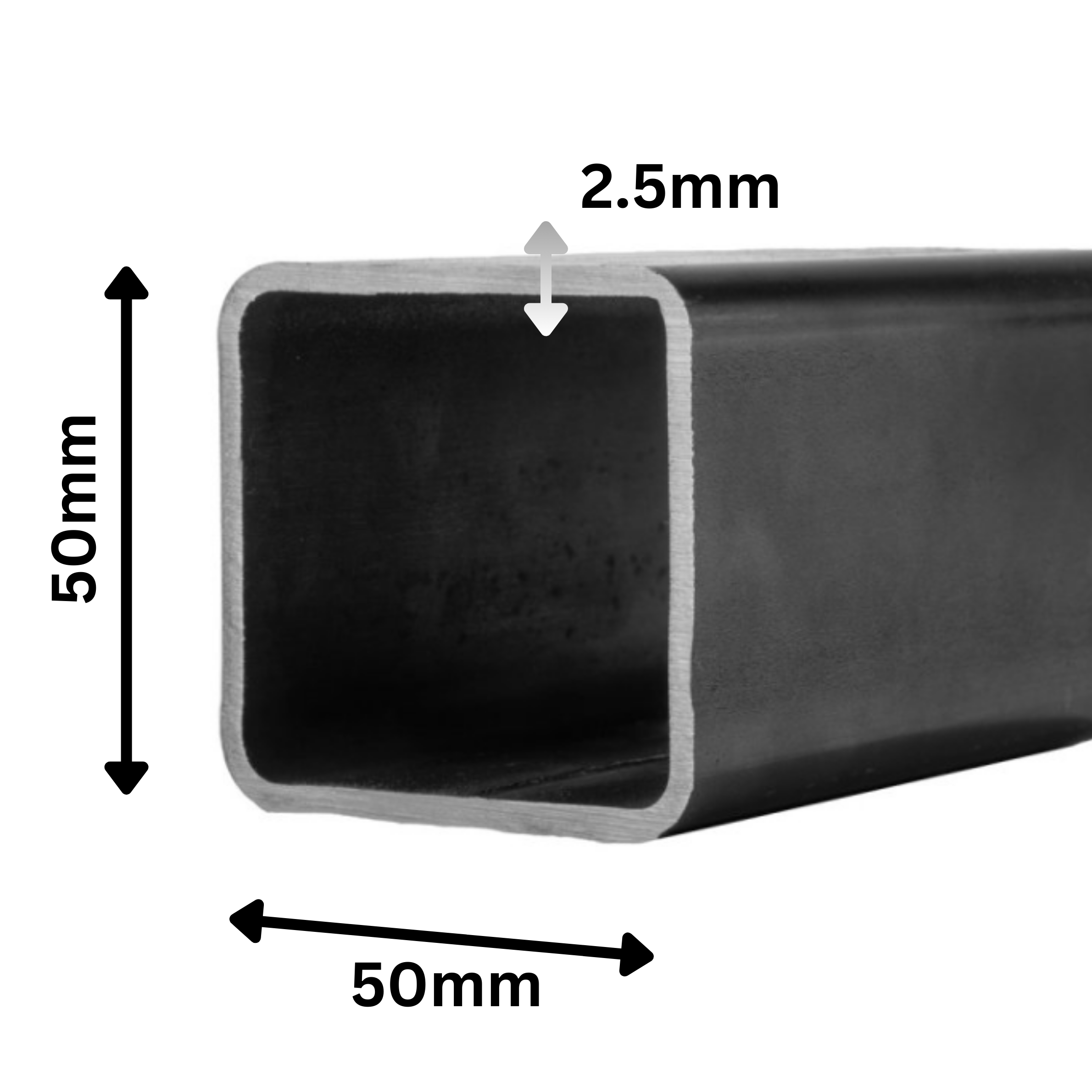

– Material: Mild Steel

– Box Section: 50 x 50 x 2.5 mm mild steel hollow box section (SHS)

– Internal Frame (if applicable): Steel angle

– Gate Arch (if applicable): 50 mm x 50 mm mild steel hollow box section (SHS)

– Country of Origin: 100% bespoke manufacturing within the UK, utilising British steel

– Treatment: Galvanized (optional)

– Finish: Powder-coated (optional)

Treatment

Galvanizing Defined

Galvanisation is a process of applying a protective zinc coating to steel to inhibit rust formation. Hot-dip galvanisation, in particular, offers substantial longevity, providing protection for up to 50 years in rural environments and around 25 years in more corrosive settings, as advised by galvanising professionals. Unprotected steel exposed to environmental conditions is susceptible to rust; the corrosion rate will depend on specific local environmental factors.

Powder Coating Defined

Powder coating involves an electrostatic application of powdered paint, which is subsequently polymerised under heat to form a durable coating. This method can extend the lifespan of the paint finish up to a decade; however, manual paint application may require more frequent maintenance due to potential flaking. While powder coating offers a layer of protection against rust, its effectiveness does not match that of hot-dip galvanisation.

Galvanisation and Powder Coating

It is feasible to apply both galvanisation and powder coating processes to the gate, which would enhance its durability and aesthetic appeal.

Infill

Infill Specification

The infill comprises tongue-and-groove composite boards made from eco-friendly, recycled timber and plastic. A range of colours and finishes is available, ensuring aesthetic versatility. The composite boards exhibit vibrancy, resilience and impervious to rot or to warp, and no pre-installation staining, treating or painting.

Cost Compare

Market Price Considerations

End users must comprehend the variances in gate pricing, particularly in the absence of industry expertise.

Structural Integrity: Our gates utilize a 50 x 50 mm box section; in contrast, numerous competitors produce gates from a smaller 30 x 30 mm box section. This fundamental difference greatly influences the strength and sturdiness of the gate.

Finish Treatment: Many metal gates lack galvanisation, which can significantly reduce costs. In contrast, we prioritise galvanization. We acknowledge that gates will need fettling, due to the rough texture left after being galvanised.

Finish Quality: Competitors often omit the labour-intensive process of fettling a gate for cost-cutting purposes.

Welding Quality: The quality of welds constitutes another primary distinction. Our methodology incorporates mitered corners (cut at 45 degrees), a technique not universally employed by other manufacturers, resulting in our welded gates having a superior finish.